Wicket Bags

Custom Manufacturing of Wicket Bags

Contact Us Today For More Information

Are you looking for a more effective plastic bag solution to package your products?

Are you losing efficiency on your production line because your operators are spending too much time handling individual poly bags?

If you answer yes to either of these questions, then wicket bags may be the answer!

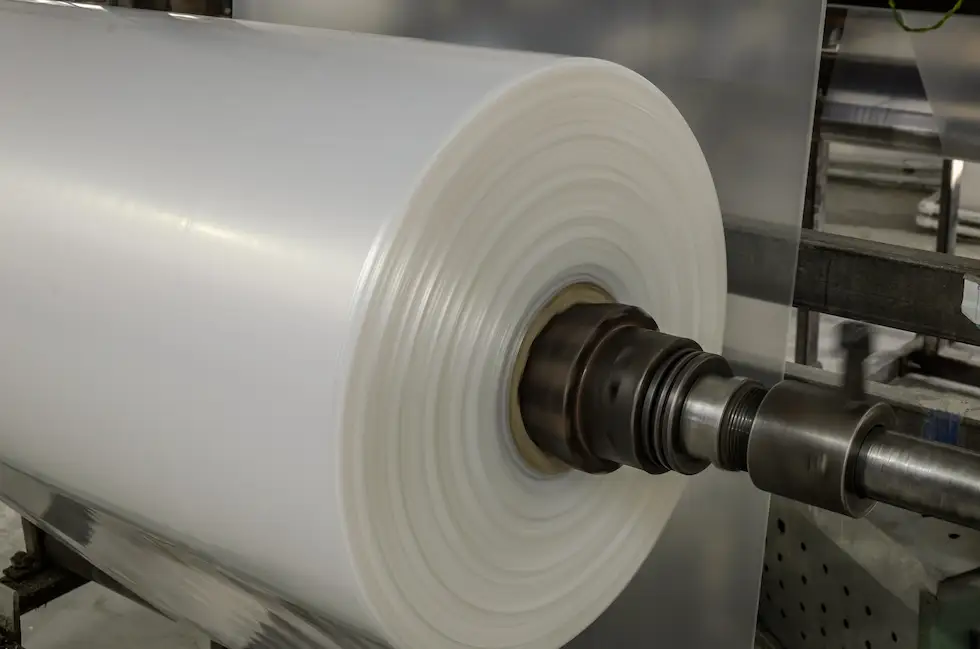

At DeerPak Industries, we have been manufacturing all types of plastic bags for industrial use, which includes wicket bags. Wicket bags help our customers increase their packaging speeds and efficiencies which saves money and time and leads to increased profitability.

Do You Need Wicket Bags?

If your business relies on fast, hygienic, or high-volume bagging, then dependable wicket bags might be the right solution. Consider these bags if you meet the following criteria:

- Package food, bakery goods, or fresh produce.

- Use automated or semi-automated packaging lines.

- Sell items in bulk quantities.

- Need custom-printed bags to support branding.

DeerPak Industries offers fully customizable wicket bag options, including branded printing, color matching, and tailored sizing to meet your product’s unique specifications.

If you are looking to purchase wicket bags, then please reach out to us today. We can help you decide on a custom order of wicket bags with our custom manufacturing capabilities. As well as go over all of the pricing details regarding these bags. When you reach out, we can go over the other types of custom bags available, too.

What is a Wicketed Bag?

Learn More About How These Bags Are Used on a Daily Basis

Wicket bags are stacked plastic bags that get arranged neatly on a wire wicket and gets held in place with rubber washers and, sometimes, a chipboard header. Wicket bags typically have a 1.5″ lip with starter notches and/or side notches.

In general, these bags get manufactured with some different features, including:

- with a bottom gusset

- full or butterfly vents

- perforations

- printing

- color tint

On top of that, these bags can be made with permanent or resealable tape for easy closing.

A full wicket of bags usually consists of 100 or 250 bags per wicket. However, this option can be customized depending on the size and gauge (thickness of material) of the bag.

Since wicket bags get stacked together after their manufacturing, they will improve anybody’s packing process. During the manufacturing, these bags can include fully or semi-automatic packing equipment that further increase packing speed and eliminates the unpacking of bags from a box one at a time. Save time by packing and packaging when you use wicket bags.

Since we are an in-house manufacturer, we can provide you with the exact measurements for the plastic bags. Many people find that having neatly stacked bags of any size increases the speed at which packaging operators can complete their tasks and the increased efficiencies offset the increased cost of the bag.

Wicket Bags Benefits

Whether you’re looking for retail-ready packaging or industrial-grade protection, wicket bags offer a practical, efficient solution that supports your brand’s quality and performance.

Wicket bags offer several benefits that make them an ideal choice for many applications, particularly in high-speed production environments. Here are some of the most common benefits of wicket bags.

- Customization: Wicket bags can be tailored in size, thickness, and print design to meet specific needs, creating attractive packaging solutions that enhance product presentation and effectiveness.

- Fast Handling: Speeds up manual and automated bagging processes.

- Reduced Contamination: Minimizes contact and cross-contamination.

- Efficiency: Wicket bags are engineered to support high-speed production, enabling quicker bagging processes in both manual and automated operations. This improved efficiency helps lower labor costs while boosting overall productivity.

- Protection for Product: Wicket bags are made with high-clarity film that shields contents from dirt, moisture, and damage. This enhances the product’s appearance while maintaining excellent visibility for display.

- Versatility: The wicket design keeps multiple bags securely bundled together, reducing the frequency of pack changeovers and streamlining operations.

- Clean Presentation: Keeps stacks organized and protected.

These benefits make wicket bags a staple in the packaging industry, especially in food, bakery, and industrial applications.

Wicket Bags FAQs

Frequently Asked Questions About Wicket Bags

How Are Wicket Bags Designed?

Wicket bags are available in different sizes. These bags have a shoulder and a leg and the wicket size is referenced to as the shoulder width by the leg length. In other words, a 5″ x 4″ wicket has a 5″ shoulder and a 4″ leg. When you turn to DeerPak Industries for the manufacturing of wicket bags, you have the option to customize them as you please. Common sizes for these bags range from 2” x 2.5” to 14” x 6” and the wickets can be with-ball-end or without-ball-end (plain end).

Who Uses Wicketed Bags?

Wicketed bags are offered for both food and non-food packaging. These bags can be manufactured in many sizes, which allows them to be used for a variety of reasons. Many food packaging lines are equipped with automatic packing equipment. And many industrial packaging lines are equipped with workstations that are designed to hold the wicket of bags. This way the packaging operator is free to easily remove a bag from the wicket after the product is placed inside. The use of these bags speeds up any packing process.

How Do You Seal Wicket Bags?

Wicket bags are very easy to close. You can use tape to close them. Zipper closures can also be an option in a customizable way. The most traditional closure options are heat sealing and zip ties. There are a number of options available for protecting your product once inside the bag, too. All of these features make for a great packing bag.

What is the Cost of Wicket Bags?

As with any custom manufactured plastic bag, the cost of it is dependent on the specific design. There are so many options available to you as a buyer when it comes to wicket bags, so it is hard to give an exact cost. Wicketed bags are normally priced in per thousand quantities. The end price depends on the size, the thickness of material, and the value-added features necessary to meet your specifications. We can consult with you to provide you with a fair and accurate estimate for the cost of manufacturing these custom wicket bags.